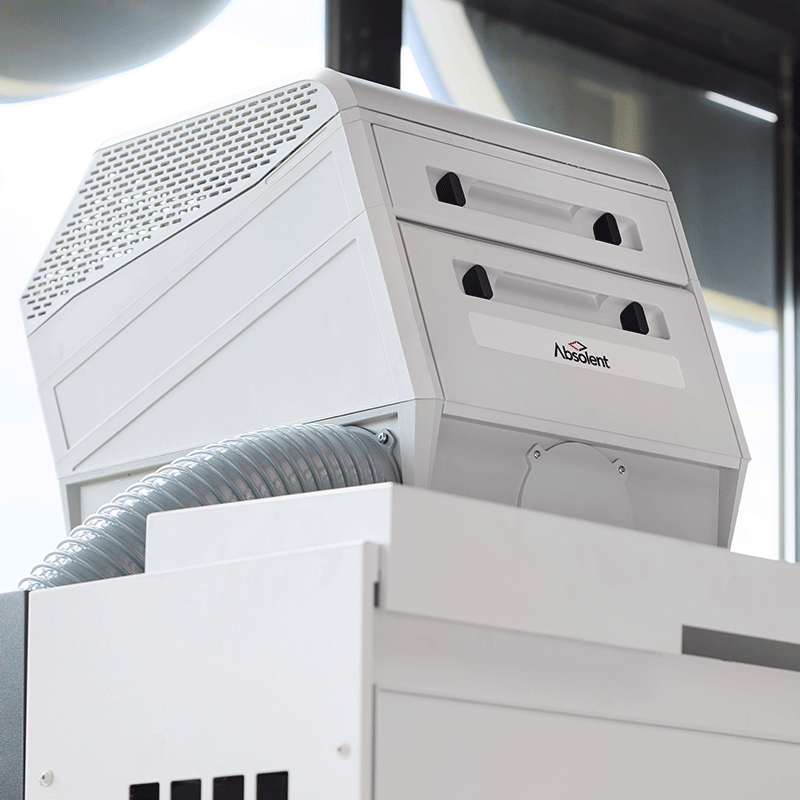

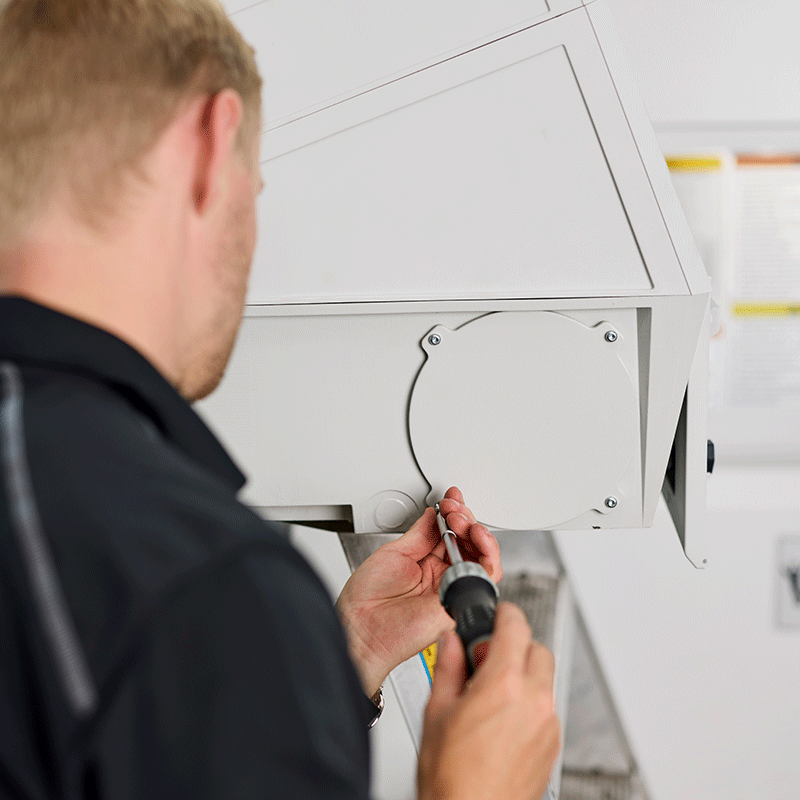

Plug & Play Installation

Factory-set airflow and intelligent fan control remove the need for manual balancing and allow instant startup. Quick installation, flexible mounting options and multiple connection points make AW easy to integrate into existing production lines.

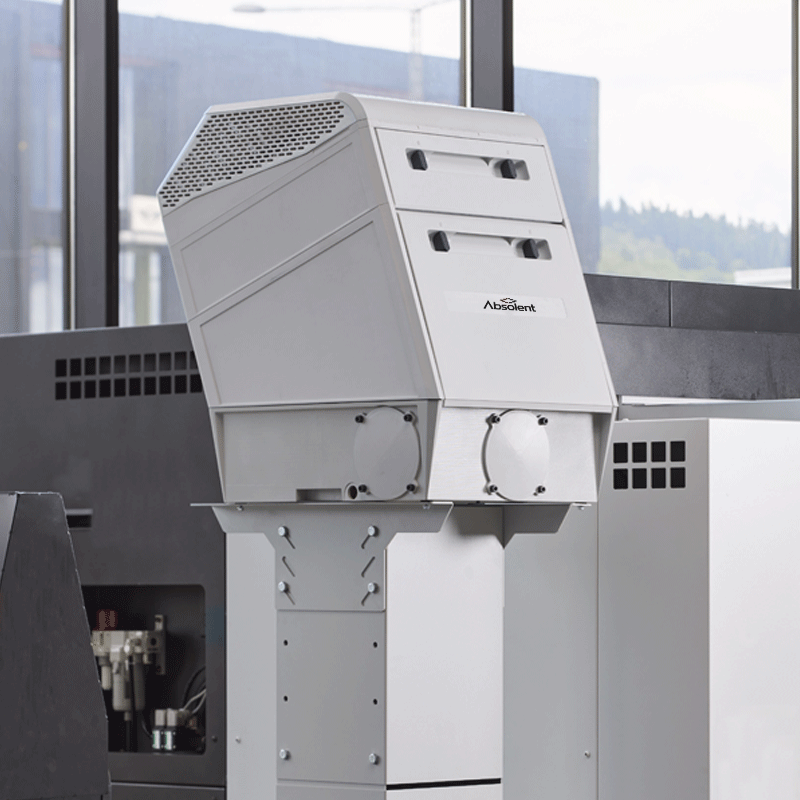

Compact & Lightweight

Starting at only 24 kg and with a footprint of 472 × 508 mm, AW is compact enough to mount, move and fit directly on the machine, even in the tightest spaces.

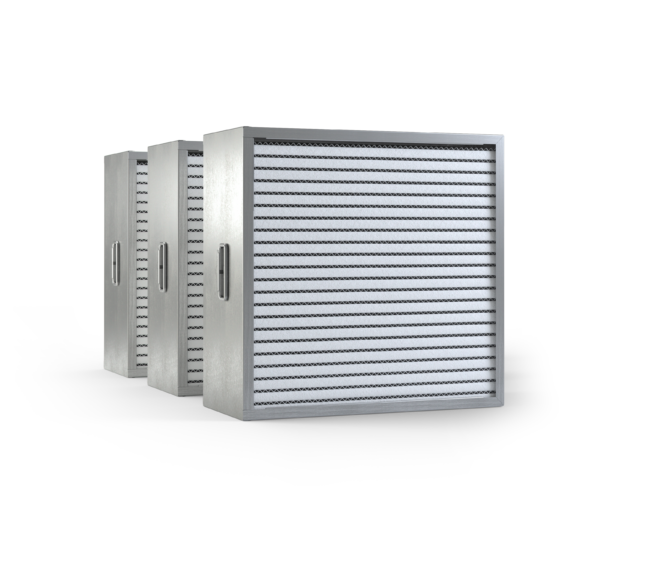

Unmatched Filtration Power Density™

Achieve maximum filtration per cubic metre, reduce operating costs and deliver superior value to your customers with our high-efficiency filter solutions.

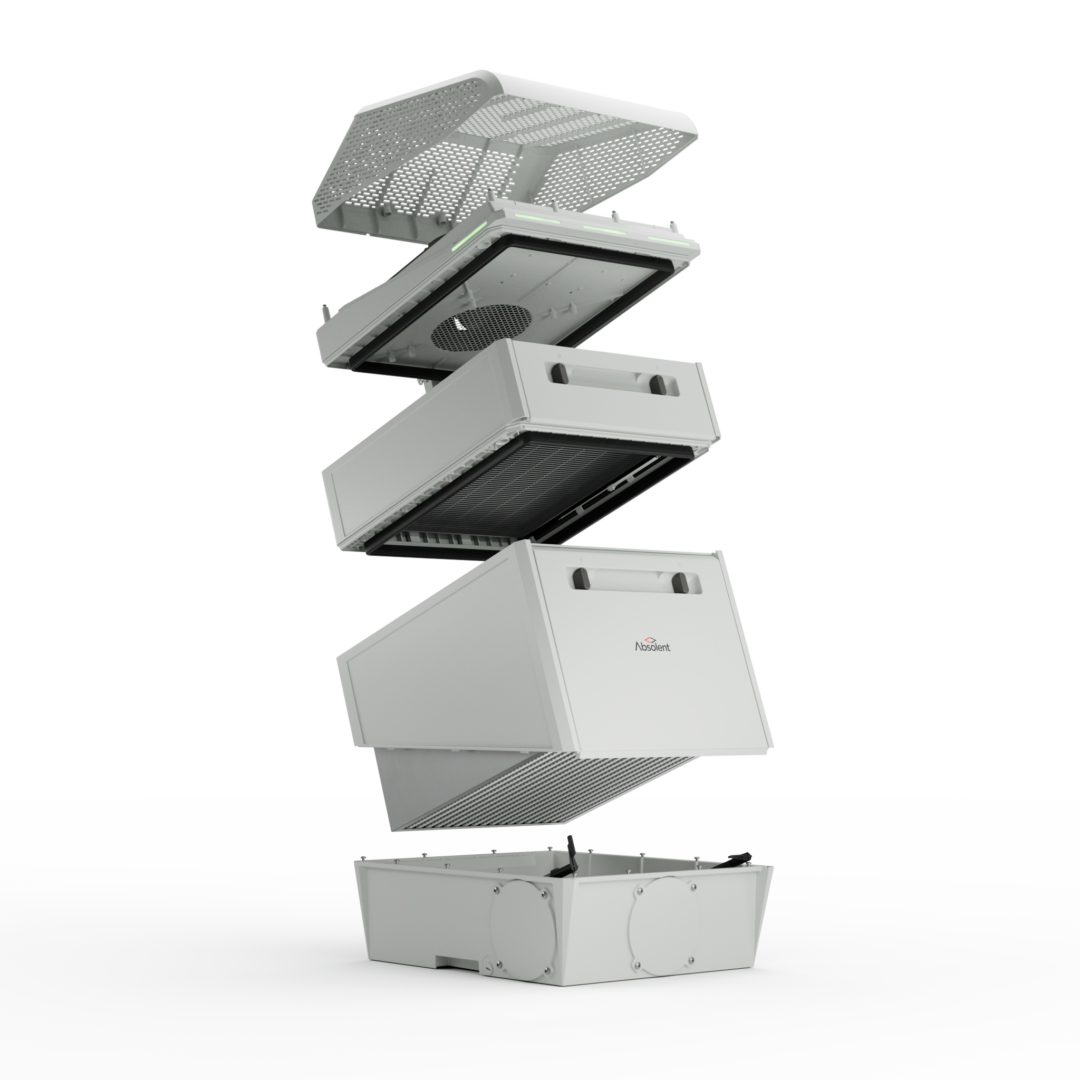

Designed for Minimal Maintenance

AW uses our self-draining Catch & Release™ technology to prevent oil build-up inside the filter cassettes. This extends filter life and enables continuous operation year-round — up to 8,760 hours. Service is minimal, with light cassettes that are easy to replace and long intervals between changes. The result is fewer shutdowns, less downtime and a lower total cost of ownership.

Stable Conditions for High Precision

AW is designed with a balanced fan and optional anti-vibration mounts that minimise vibration at the source and prevent transfer to the machine. This safeguards accuracy in delicate processes and ensures consistent output quality in micro machining.

Pre-calibrated Safety Boost

From day one, AW runs at the right capacity with five pre-calibrated airflow levels. No setup or fine-tuning required. When the CNC door opens, Boost Mode can be set to automatically raise airflow for 30 seconds, clearing mist quickly and protecting operators with cleaner, safer air.

Smarter Airflow for Sustainable Efficiency

The AW range combines an energy-efficient EC fan with EcoDrive® control, automatically adapting airflow to demand to reduce power use, extend filter life and keep production sustainable.

Clear LED guidance

The AW unit features an LED interface that communicates status through simple colour codes. At a glance, you see if the unit is running normally, needs attention, or if a filter cassette will soon need replacing. This gives you time to plan service and order filters in advance, keeping maintenance predictable and your unit running reliably.

Plan ahead with IoT Insights

AW can be equipped with IoT connectivity that gives a clear view of performance and filter status. Real-time data helps you plan service in advance, avoid unplanned downtime and integrate air quality monitoring into your factory systems.