What is Oil Smoke?

Oil smoke, like oil mist, consists of airborne oil droplets. The difference is that these particles are smaller than the oil mist particles and they usually come in larger amounts. The size of the oil smoke particles ranges from 0,1 – 1 µm. Oil smoke can sometimes have a blueish colour. It arises when machines are working at high speeds and/or are using high coolant pressures. It can also occur during minimal quantity lubrication (MQL) or during hot manufacturing processes such as die casting, hot/cold forming, hardening/ bolt making. Oil smoke could also be encountered in other industries such as food processing, rubber and plastic processes and in the textile industry. Just as oil mist, the oil smoke is measured in mg/m3. It is not unrealistic that just one machine in a workshop emits 6 barrels of oil into the air each year. No matter the country, the threshold limit for what is allowed in a workshop is normally the same for oil smoke and oil mist. Consult Absolent or our representatives and we are more than happy to assist you with measurements or project designs to suit your production. Read more about this here.

How to Capture Oil Smoke?

The most common and effective way to capture oil smoke is to extract the contaminated air as close to the source as possible. The more enclosed and air tight the process is, the less air quantity and energy is required. If a filter unit from Absolent is installed it will effectively extract the air from the enclosure and protect the worker and the environment from the contamination. If the machine is partly open, Absolent or our representatives can assist you with accessories, hoods or enclosures that will make capturing the polluted air both easy and energy efficient

Absolent has the Solution!

An Absolent filter unit contains several filter cassettes. The filter cassettes consist of carefully put together our filter materials, always mixed and matched to suit the customer’s needs. That is what makes our products so special. Just like a bike and a truck are both be vehicles, but far from the same, we don’t have just one filter unit to suit all needs. Instead we have one filter unit to suits each process. Depending on how heavily polluted the air is – we choose the truck or the bike – or something in between.

How does it Work?

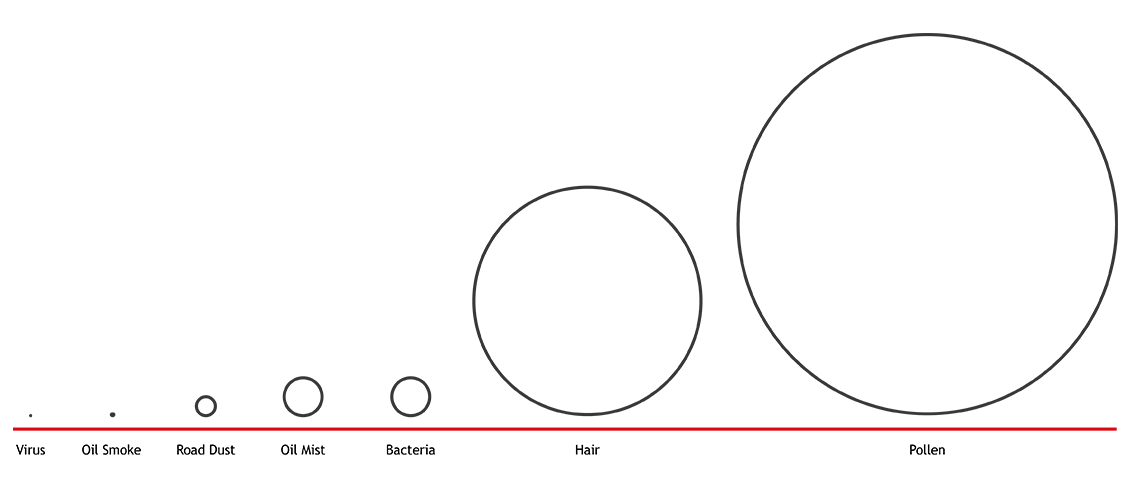

Air contaminated by oil mist and/or oil smoke passes into the bottom part of the filter unit where the filtration begins. The big, heavy particles are unable to follow the air that is flowing upwards. These oil droplets fall down and are collected in the bottom section and pumped out of the filter unit. The oil can then be returned back into the machine, to an oil collection barrel or to a central cleaning for re-circulation. The remaining pollution passes through the first Absolent filter cassette where oil particles are captured and then drained downwards, away from the cassette. This is what we call the “Catch and Release” principle. This is, of course happening while the machine is operating at full speed. The filter unit is designed for 24/7 operation so there is no need for downtime to drain or clean the cassettes which allows you to fully focus on your manufacturing. Depending on what filter unit you have the air is sometimes passed on through yet another filter cassettes where most of the remaining particles are filtered away. The Absolent filtration process always ends with a HEPA filter class H13, which ensures that the air is 99,97% free from harmful particles larger or equal to 0,3 microns. When the filtration process is done what happens to the air depends on the local regulations. It can either be returned directly to the premises or be passed via a heat exchanger before it’s returned back into the workshop. Why waste heated air that can be used elsewhere in the premises? For more information on how Absolent can help you save energy, click here.